Secure Energy Transportation!

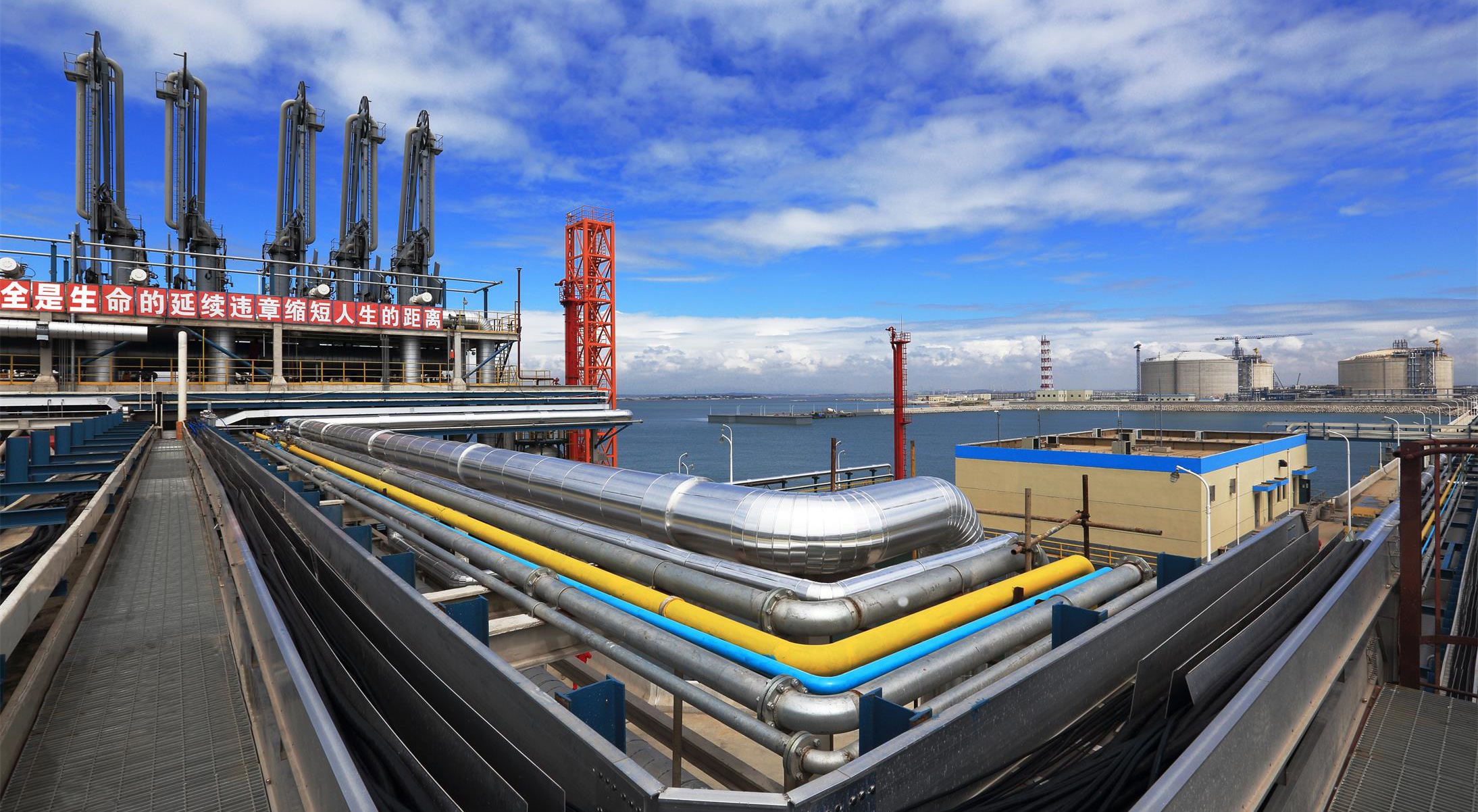

China's liquefied natural gas (LNG) imports have increased rapidly. In order to facilitate natural gas

transportation, the natural gas is usually liquefied. Its volume is 1/625 in the standard state.Natural

gas is compressed and cooled to its boiling point (-161.5 ℃) and then becomes liquid. Liquefied

natural gas is usually stored at 0.1MPa @ -161.5℃ cryogenic storage tank. Polyurethane

insulation material has excellent cold insulation performance, which is the first choice for LNG

receiving station and pipelines.

-

ADVANTAGE

ADVANTAGE -

PROCESS

PROCESS -

TECHNOLOGY

TECHNOLOGY

ADVANTAGE

Rigid polyurethane foams have unrivalled insulating properties which, together with excellent mechanical properties, high heat resistance and low water absorption.Polyurethane foam has good compatibility with many materials, provides good adhesive force, and is tightly bonded with substrate.

PROCESS

LNG cold preservation pipe insulation, use prefabricated polyurethane and shells, to the scene with the pipe clamp and aluminum surface when arrive on job site. LNG tank cold preservation materials are mostly polyurethane spraying process.

TECHNOLOGY

Complies to international technical standard.

Application

GB Standard

Typical Performance

|

Propduct properties |

PIR |

PUR |

|

Compressive strength(PIR) |

≥0.22 MPa |

≥0.2 MPa |

|

Closed-cell rate |

≥90% |

≥90% |

|

Water absorption rate (Volume) |

≤4.0% |

≤5.0% |

|

Vapor permeability coefficient |

≤ 5.8 x 10-9g/(Pa.m.s) |

≤ 6.5 x 10-9g/(Pa.m.s) |

* GB 50264-2013 Code for design of industrial equipment and pipeline insulation engineering